Custom Machining Services

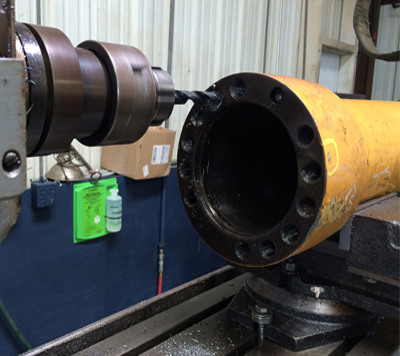

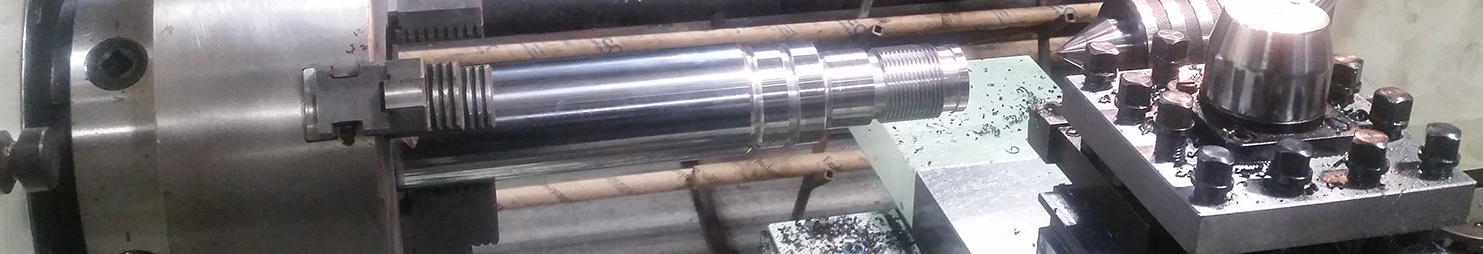

Our facility is equipped with three GAP bed lathes and two knee mills. We have state-of-the-art equipment to provide the best product available.

An engine lathe is a horizontally shaped piece of machinery that is most often used to turn metal manually. By turning the metal and using special cutting tools, the lathe is capable of forming the metal into specific shapes. As its name implies, it is often used to create metal pieces for use in an engine, whether it be for an automobile, a tractor, a boat, or any other motorized vehicle or machine.

A knee mill is a type of vertical milling machine where instead of the entire table being stationary, it is able to move along the y, or vertical, axis, a direction in which the workpiece can move in relation to the milling tool shaping it. This is different from standard milling machines, where the table can only move along both x, or horizontal, axises, and the head, consisting of the usually stationary top slide and spindle, is responsible for all drilling and boring movements along the y-axis. The knee mill is also different from most milling machines because of its head, which can also move along an x-axis. Bridgeport mills are knee mills and, due to their movement capabilities, they are able to take on a wide variety of workpiece sizes.